It’s an important step forward. Extending the life cycle of materials used in the construction of tyres is a major goal for everyone at Continental and we’re pleased to move a step closer. The introduction of a new technology enabling the use of recycled plastic from drinks bottles in tyre construction allows us to completely replace the use of conventional virgin PET (polyethylene terephthalate) in the construction of tyre carcasses.

How plastic bottles end up in tyres

Polyethylene terephthalate is the most common thermoplastic resin in the polyester family. Yes, that polyester that you wear pretty much every day. It’s also used to make drink bottles and car tyres. The idea of using polyester to make tyres might seem a little strange but it makes perfect scientific sense and its use has become indispensable to the manufacturing process. PET is used to make up the carcass of the tyre, forming the textile cords that run from bead to bead (the inner circle of the tyre).

The horseshoe-shaped layer sits just above the inner tyre. Its impact is felt in tyre durability, load capacity and comfort. It effectively becomes the backbone of the tyre. Importantly, it maintains its shape even at very high temperatures.

A conventional car tyre will have around 400g of polyester yarn in the carcass. We use PET in nearly all of our tyres and it’s traditionally sourced from what is known as virgin PET, a polyester yarn made from petroleum.

From both an environmental and sustainability viewpoint, PET is far from ideal. It’s energy hungry to produce from scratch and doesn’t break down. The very same reason that makes it good for tyres, makes it bad for the landfill, as it will stick around. That is, unless another use can be found for it, which is exactly what we’ve done.

Reuse, Recycle, Repeat

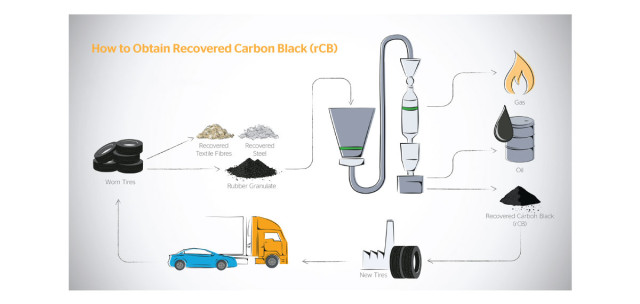

Claus Petschick is the Head of Sustainability at Continental Tyres. He believes a circular economy is the only environmentally friendly future business model. In a traditional linear economy, a natural resource is created and then discarded after use. It becomes a waste product, polluting the environment and causing harm to wildlife.

Circular economies are different. They separate growth from the consumption of finite resources, looking instead to recycle products so they can be used in new designs and new products. It preserves natural resources, often reducing energy use in the production process on the way through, before finding a way to the consumer as a product once more. Then the process gets repeated, again and again.

"Our ambition is clear” states Claus Petschick. Continental wants to “completely close our product and resource cycles".

The first tyres with recycled PET bottles are available now

Tyres made from recycled PET bottles are described as including ContiRe.Tex technology, which is our name for the process. The tyres themselves will be labelled with ‘Contains Recycled Material’ on the tyre sidewall.

Tyres including the recycled material currently include the Continental PremiumContact 6 and EcoContact 6, in 5 sizes each. We hope to extend the use of recycled PET across the range over the next few years, as we move closer to the 2050 goal.

We're not at the finishing line yet though

The sustainability efforts of tyre manufacturing will not stop with PET. Over the past few years we have been busy developing a new sustainable source of rubber, which will have a profound impact on the carbon footprint of the manufacturing princess and help save precious land near the equator. Making rubber from the Russian dandelion plant has already started with tyres produced using this rubber featuring in the Extreme E Racing Series.

At the core of everything remains safety. We want the future of mobility to be as safe as possible. For people and the planet.