Breakdowns have been a frustrating but inevitable part of driving since the invention of the automobile. In the early 1900’s, many of the breakdowns were caused by tyre trouble. Whilst the internal combustion engine powering the vehicle was a marvel of modern technology, both tyres and the infrastructure needed to support driving lacked investment. That changed over time, with tyres quickly becoming more robust, making the driving experience more comfortable and safer, as well as more reliable. Today, tyres are less likely than ever to result in a breakdown. Tomorrow, they might even prevent issues before they happen.

The Art of Fixing a Flat

One of the issues with early automobile excursions was a lack of roads. Governments were playing catch up with the new technology and yet to start building the smooth highways we know today. It wasn’t until the Main Highways Act 1922 that New Zealand started to really form a cohesive plan to develop the infrastructure needed to support travel by automobile. This meant the early decades of car travel were across loosely formed roads frequented by stagecoaches pulled by horses. They were frequently muddy and heavily rutted by the solid stagecoach wheels.

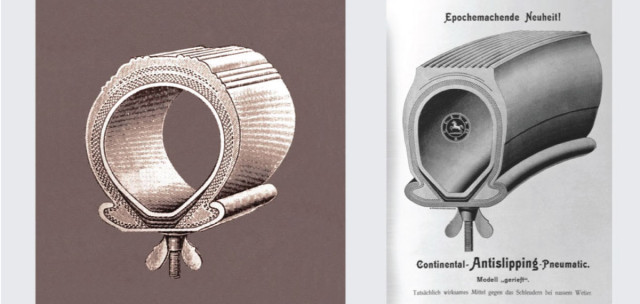

With muddy roads, one of the issues of early tyres was a lack of traction. This led us to develop the first ever automobile tyre with a patterned tread, in 1904. That development heralded the start of thinking more critically about tyres and is the genesis for car tyres as a specialist area. Importantly, it defined an approach that we continue to follow over 150 years later. An approach centred on research and development, taking the time to innovate, test and retest.

While traction was improved, early tyres still suffered from the less-than-perfect surfaces. Punctures were amongst the most common reasons for a breakdown. There were no recovery services to speak of and while the Automobile Association began in Britain in 1905, for the first 30 years or so its main focus was on trying to help motorists avoid getting speeding fines! So when the inevitable breakdown did happen, there was a need for the motorist to be relatively skilled in mechanics. Anything less than considerable proficiency would see the driver suffer the ignominy of having their sporty new car being towed by Horse.

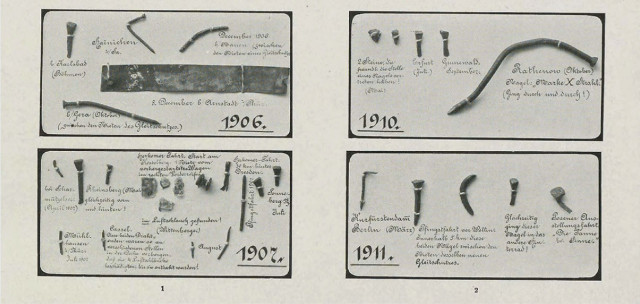

With early tyres, a hole less than 5mm in diameter could easily lead to the rapid loss of tyre pressure. Often, this would mean a small nail was all that was needed. Or even the type of jagged stone we eagerly ride over today. So it’s easy to imagine, given the state of the roads, how frequently the problem of a flat tyre might present itself to the motorist.

Tyre Technology Comes of Age

As automobiles became more popular, efforts to aid the safe mobility of motorists increased. To begin with, this meant sharing information and by 1910 we were providing instructions on how to change a tyre. Educating motorists was a simple yet effective strategy. It was also necessary given how new much of the technology was. Remember, the first ‘modern’ bicycle (i.e with wheels the same size) wasn’t invented until 1895 and for most the bicycle was considered complicated machinery.

In 1928, we began providing rubber inserts to protect against damage caused by nails. Three years later we unveiled a self-vulcanising rubber plate for motorcycle tyres. Everything was geared towards a quick repair and getting the motorist back onto the road. Those roads were becoming better too. More and more, Governments were realising the benefits of roading networks for the transportation of goods and services. They connected the country and made life easier for everyone.

As the roads improved so did the speed of the vehicles using them. Tyre technology had to advance not only in order to resist any sharp protrusions on the road but also to resist the forces (and heat) of faster and faster cars. Then, in 1943, we were awarded a patent for the tubeless car tyre. Today, we’d refer to such an innovation as a ‘game-changer’. They were certainly more reliable tyres, so much so that by the 1950s Sterling Moss was using them as he raced to Grand Prix victory after Grand Prix victory.

Over time, the sight of a vehicle at the side of the road, jacked up as someone changed the tyre, became less and less frequent. By the second half of the last century, breakdown services had become commonplace too and there was a reduced onus on the driver to know how to effect any repairs. The AA Breakdown Services had erected their own phone boxes, positioned in strategic areas where motorists could walk and use them to connect with help. Then, of course, mobile phones arrived and getting help was easier than ever.

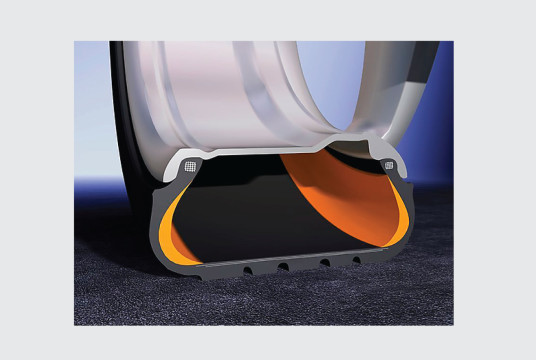

By now it’s the 1980s and the new Continental Tire System represented a truly revolutionary step. For the first time, tyres no longer rested on the rims' outer surfaces but gripped them from the outside. This opened up a range of advantages, including improved ride quality and better handling in wet weather. Perhaps most importantly, though, it meant the car could be driven even with a flat tyre. Unfortunately, production remained limited at the time due to the high costs.

A Puncture Shouldn’t Deflate Progress

Today, it’s pretty rare to see someone changing a tyre by the roadside. There's a number of reasons for this, including significantly improved puncture resistance in tyres, and technological developments that allow some tyres to keep on going (if only for a limited time), in the event of a puncture.

Modern tyres will mould, shape and bend themselves around the (generally) much improved road surfaces. When a sharp edge does breach the rubber defences, the result is relatively more likely to be a slow deflation that is noticed before the tyre has lost pressure completely, particularly if the vehicle is only running at lower speeds.

And some tyres can keep running even in the case of lost inflation pressure. While standard radial tyres will suffer irreparable damage if run at very lower pressures for any length of time, a Self-supporting Runflat tyre - the new generation of that idea we developed in the 1980s - will allow drivers to travel up to 80 km at a speed of up to 80 km/hr, even after loss of inflation pressure. There's a few things to be aware of though - Self-supporting Runflat tyres can't be mixed with other tyres on the same vehicle, and it's illegal to run them without a tyre pressure monitoring system on the vehicle as there's otherwise no way to know when a puncture has occurred. We recommend only running them on vehicles designed to be fitted with them, as they have much stiffer sidewalls than regular tyres and require quite a different suspension setup.

An alternatively technology to keep motorists mobile is ContiSeal. A sticky, viscous sealant layer in the interior of the tyre that can instantly seal 80% of punctures. Air remains trapped inside and the tyre inflated, with no impact on the handling of the car under normal circumstances.

Lastly, preventative maintenance technology is proving increasingly valuable in mitigating vehicle problems before they become serious – and tyres are no exception. Approximately 40% of sudden wheel breakdowns are due to underinflated tyres. Our Tire Pressure Monitoring System (TPMS) alerts drivers as soon as pressure drops, providing time to find a nearby garage with an air pump to reinflate the tyres to the correct inflation pressure.

Smart Tyres for Safer, More Enjoyable Journeys

Tomorrow’s tyres will do even more. We’re currently working on systems that will register abnormal temperatures in tyres, detect changes in tread depth… and tyres which even repair themselves as you drive.

Continental C.A.R.E (Connected, Autonomous, Reliable and Electrified) is the name given to tyres with sensors which wirelessly communicate vital information on each tyre to the car’s main operating system. Drivers will be provided with real-time feedback on tyre performance while integrated centrifugal pumps automatically add air if required, optimising the pressure for each driving situation and delivering vital top-ups if pressure is lost.

Ultimately, increasingly intelligent tyre sensors bring a range of benefits, including reduced repair and maintenance costs, maximum fuel efficiency and a safer, more comfortable ride.

They might not completely make breakdowns a thing of the past just yet. But they’ll certainly help.